Aerospace R&D at Cape Canaveral

Building Safety into Outer Space Manufacturing

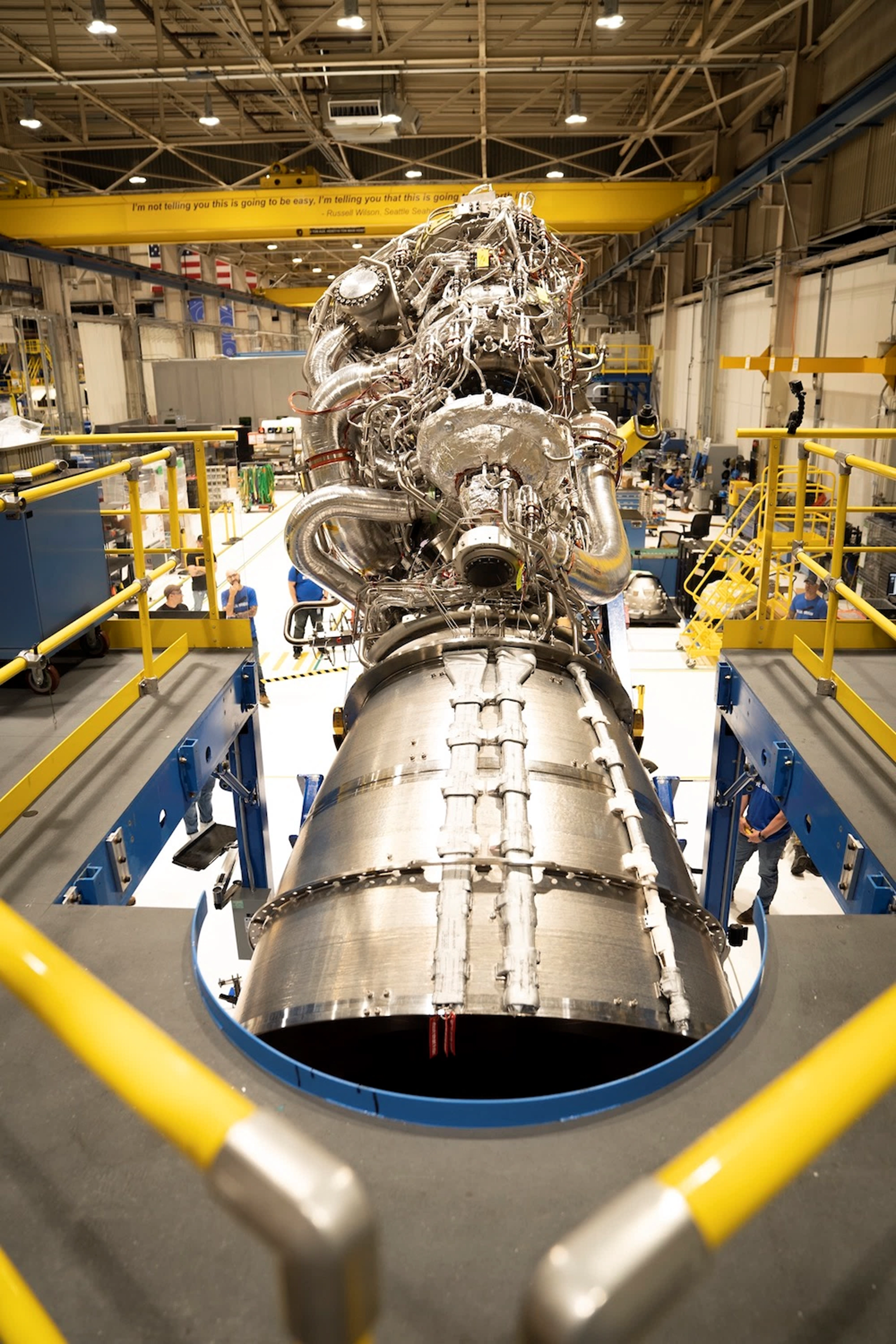

At

Cape Canaveral, a leading spaceflight company is developing a large-scale manufacturing facility to support assembly, testing, and

encapsulation of spacecraft systems for space exploration missions. At the heart of this complex is a specialized test chamber, where

fully assembled hardware undergoes high-pressure proof and leak testing before advancing towards launch readiness. No vehicle moves

forward without clearing this critical checkpoint, which functions as a safeguard for both mission success and personnel safety.

At

Cape Canaveral, a leading spaceflight company is developing a large-scale manufacturing facility to support assembly, testing, and

encapsulation of spacecraft systems for space exploration missions. At the heart of this complex is a specialized test chamber, where

fully assembled hardware undergoes high-pressure proof and leak testing before advancing towards launch readiness. No vehicle moves

forward without clearing this critical checkpoint, which functions as a safeguard for both mission success and personnel safety.

IntegralRSG collaborated with the Design-Builder to embed protective measures into this high-consequence environment. Our specialists defined performance objectives to confront exposures of shock overpressure, fragment, and impulsive noise hazards. We led the development of construction contingencies to ensure that the chamber could contain the effects of an accidental component rupture while preserving surrounding operations. We aligned structural and architectural solutions with stringent aerospace and Defense safety requirements.

The result is a resilient testing environment that protects people, secures infrastructure, and strengthens a mission-critical step between

factory floor and launchpad—advancing the reliability of future space exploration. We’re honored to help streamline humanity’s push into

beyond-Earth-orbit missions.

| Owner: |

Confidential |

| Size: |

200,000 SF |

| Location: |

Kennedy Space Center, FL |

| Collaborators: |

The Austin Company |

| Delivery Method: |

Design-Build |